- Industrial Materials - Bars Overview

- Maximizing Efficiency with Centerless Grinders

- Difference Between Precision Steel Pipe and Cold Drawn Pipe

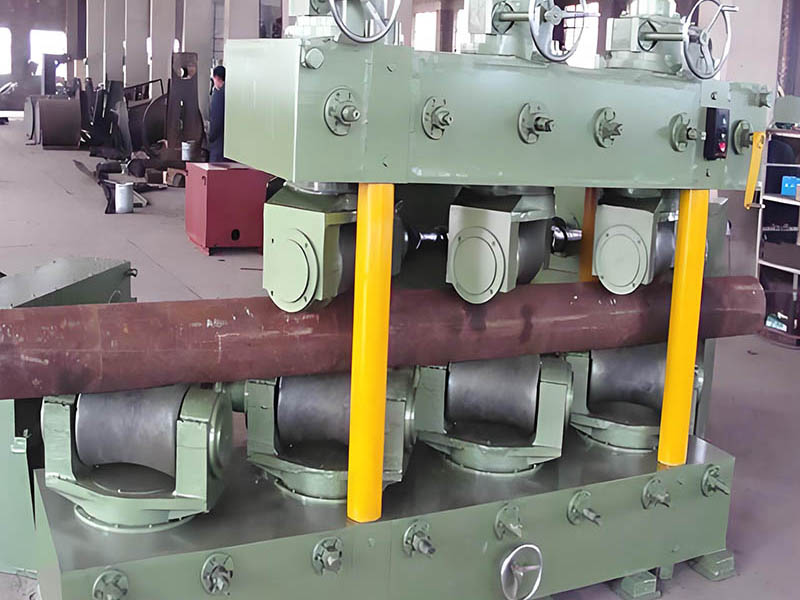

- Straightening Machines: Types, Functions, and Applications

- Essential Maintenance and Refueling Guide for Centerless Grinders

- Steel Peeling Machines: Advantages and Applications

E-mail:liu@mingchenggroup.com

Phone:+86 13322202758

QQ:605712576

Address:No. 20, Gangwan Street, Zhongshan District, Dalian City, Liaoning Province

Maximizing Efficiency with Centerless Grinders

Centerless grinders are precision machines designed to grind cylindrical and conical outer surfaces with high accuracy. These machines are controlled by pre-programmed numerical instructions and are known for their efficiency, rigidity, precision, and adaptability. Centerless grinders are commonly used in industries such as automotive, aerospace, air compressors, bearings, and military manufacturing, where high-precision grinding is essential.

Versatility and Processing Quality

Versatility and Processing Quality

Centerless grinders are particularly versatile, capable of processing parts that ordinary grinders cannot handle, such as shaft parts with special curves, special-shaped components, and molds requiring multi-coordinate operations. This versatility allows for a wide range of parts to be processed efficiently, making them ideal for high-precision, complex tasks.

While centerless grinders require substantial preparation time, including process analysis, program compilation, and trial cutting, these efforts are offset by the ability to reuse setups for subsequent runs. Once a part has been successfully trial-produced, the preparation time decreases significantly for repeat production, making the overall process more cost-effective.

Centerless grinders excel at achieving high precision and consistency, producing parts with excellent interchangeability and minimal human intervention. They are well-suited for medium and small batch production of critical components. However, the economic benefits are most evident when the batch size is large enough to justify the preparation time. In small batches, the time spent on setup and adjustments may outweigh the benefits, as the cutting time only accounts for a fraction of the total working time.

Maximizing Capabilities and Workflow Efficiency

Maximizing Capabilities and Workflow Efficiency

Centerless grinders are capable of performing complex grinding tasks, such as grinding torus surfaces (both convex and concave) and various combined surfaces, in addition to cylindrical and conical grinding. While they cannot complete all tasks independently, such as drilling or milling, their ability to handle multi-process grinding efficiently gives them an edge in manufacturing environments that require high versatility.

To maximize production efficiency, centerless grinders often need to work in coordination with other machines to complete all the necessary processes for a part. Proper planning and workflow management are key to ensuring a smooth and efficient manufacturing process.

Welcome to Order

Welcome to Order

Centerless grinders offer significant advantages in terms of precision, efficiency, and versatility. By understanding their strengths and limitations, manufacturers can optimize their production processes and achieve the best results. With proper planning, these machines can greatly enhance manufacturing operations, particularly for high-precision, medium to large batch production.

For more information or inquiries about our centerless grinders, feel free to contact our team. Welcome to order from us!

- Previous:Difference Between Precision Steel Pipe and Cold Drawn Pipe

- Next:Industrial Materials - Bars Overview

-

2023-09-19How The Round Steel Peeling Machine Works?

-

2023-09-19Round Steel Peeling Machine