- Main Processing Applications of Centerless Grinding Machines

- Industrial Materials - Bars Overview

- Maximizing Efficiency with Centerless Grinders

- Difference Between Precision Steel Pipe and Cold Drawn Pipe

- Straightening Machines: Types, Functions, and Applications

- Essential Maintenance and Refueling Guide for Centerless Grinders

E-mail:liu@mingchenggroup.com

Phone:+86 13322202758

QQ:605712576

Address:No. 20, Gangwan Street, Zhongshan District, Dalian City, Liaoning Province

Main Processing Applications of Centerless Grinding Machines

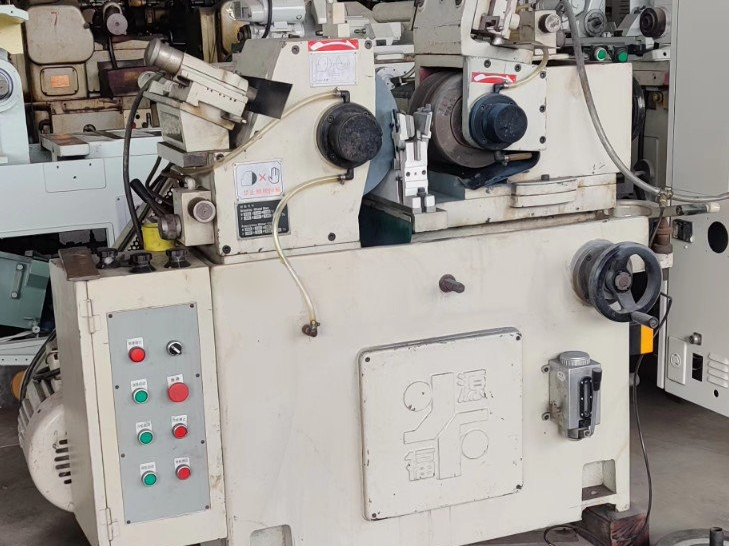

Centerless grinding machines are essential for grinding cylindrical and conical external surfaces with high precision and efficiency. Pre-programmed to meet specific machining requirements, these machines are controlled by numerical commands from a CNC system. Their versatility, high precision, rigidity, and adaptability make them indispensable in industries such as automotive, aerospace, and military manufacturing.

Versatility and Precision in Centerless Grinding

Versatility and Precision in Centerless Grinding

Centerless grinders excel in processing parts with complex geometries, such as shafts with special curves or multi-coordinate molds—tasks that conventional grinders cannot handle. These machines are indispensable in high-precision, high-volume production environments. The modular design allows them to be adapted to various applications, making them key components in industries where tight tolerances and high production rates are critical.

Compared to conventional grinders, centerless machines reduce human errors and deliver consistent precision, boosting overall manufacturing efficiency.

Maximizing Economic Benefits and Efficiency

Maximizing Economic Benefits and Efficiency

Centerless grinding machines are most economical when used for parts that are produced in large volumes. Once a part is successfully trial-produced, setup files and programs can be reused, reducing production cycle time and enhancing quality for small and medium-sized batches. However, setup and adjustment time can be longer for smaller batches, which may make them less economical than conventional grinders in some cases.

When used in grinding centers that integrate multiple processes, centerless grinders can greatly reduce processing times, improving overall efficiency.

Why Choose Us

Why Choose Us

We offer advanced centerless grinding machines built to deliver high performance, versatility, and precision. Our machines optimize both small and large batch production, providing consistent quality and cost savings. With expert support and precision technology, we help enhance your manufacturing operations.

Contact us today to discover how our solutions can elevate your production capabilities.

- Previous:Industrial Materials - Bars Overview

- Next:No time

-

2023-09-19How The Round Steel Peeling Machine Works?

-

2023-09-19Round Steel Peeling Machine